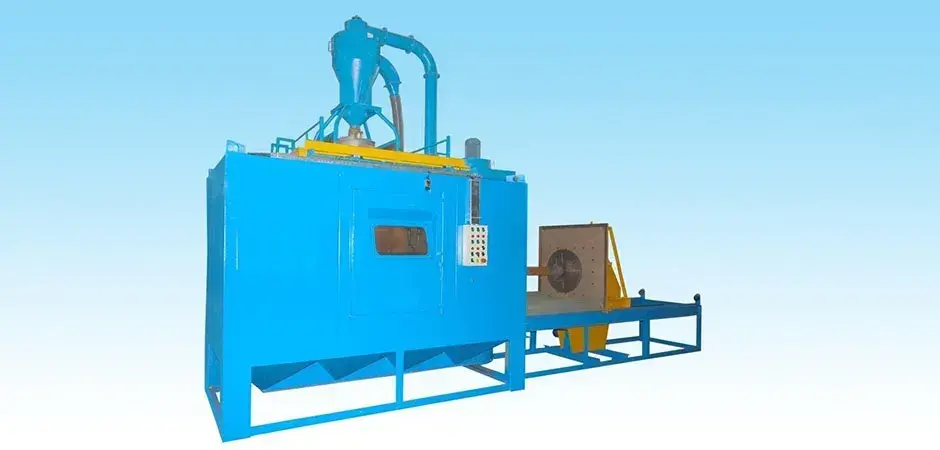

Elevate Your Rolling Mill Performance with Ghaziabad’s Leading Roll Etching Machine Manufacturers

Are you searching for reliable, high-performance roll etching machines in Ghaziabad to enhance your rolling mill operations? Look no further! We are a leading manufacturer specializing in precision roll etching solutions that deliver the surface finishes you demand.

What is a Roll Etching Machine and Why Do You Need One?

Roll etching machines employ advanced abrasive blasting techniques to meticulously modify the surface texture of rolls utilized in various rolling mills. This controlled etching plays a pivotal role in determining the quality of final products across the steel, aluminum, textile, and paper industries.

Benefits of Our Ghaziabad-Manufactured Roll Etching Machines

- Unmatched Precision: Attain the precise surface roughness (Ra value) needed for your specific applications.

- Boosted Productivity: Optimize your roll preparation processes with our efficient and user-friendly machines.

- Customization to Your Exact Needs: We tailor machine dimensions, functionalities, and levels of automation to seamlessly integrate with your existing production lines.

- Built to Last: Our robust construction and premium components guarantee long-term reliability.

- Industry-Leading Expertise: Our extensive experience in roll etching technology ensures your success.

How Our Roll Etching Machines Work

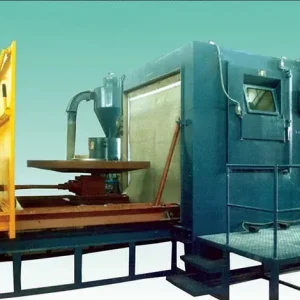

- Secure Roll Loading: Rolls are mounted onto a motorized work car within the machine’s blasting chamber.

- Precision Abrasive Blasting: Abrasive media is propelled at high pressure onto the rotating roll, generating the desired surface texture.

- Uniform Etching: Nozzles traverse automatically in synchronization with the roll, ensuring consistent treatment across the entire surface.

- Efficient Media Recycling: Our systems effectively reclaim and recirculate reusable abrasive media.

- Safe Work Environment: Integrated dust collectors maintain optimal air quality for your operators.

Key Features of Our Ghaziabad-Made Roll Etching Machines

- Adjustable gun reciprocation for customizable blasting patterns

- Automated roll rotation for perfectly even etching

- Vibratory sieve classifier to precisely control Ra values

- Integrated roll drive and track for effortless loading/unloading

- Advanced dust collection systems

- Brightly lit chamber interior for clear visibility and accuracy

Transform Your Rolling Mill with Our Roll Etching Machines

Ready to experience the difference that superior roll etching can make? Contact us in Ghaziabad today to discuss your unique requirements, explore our project portfolio, and receive a personalized quote. Let’s work together to achieve the perfect surface finishes for your rolling mill products!

Reviews

There are no reviews yet.