In Ghaziabad’s dynamic industrial landscape, maintaining surface integrity is paramount for ensuring the longevity and performance of critical components across diverse sectors. Shot peening machines play a crucial role in enhancing surface durability, fatigue resistance, and stress tolerance by imparting controlled plastic deformation through the impact of spherical media. For businesses seeking reliable shot peening solutions, partnering with reputable manufacturers in Ghaziabad is essential to access advanced equipment tailored to their specific requirements.

Shot peening machines are integral to numerous industries, including automotive, aerospace, manufacturing, and more, where the integrity of metal components is paramount. By inducing compressive stresses on surfaces, shot peening enhances resistance to fatigue, corrosion, and cracking, thereby extending component life and improving performance. As such, selecting the right shot peening machine manufacturer in Ghaziabad is instrumental in optimizing surface treatment processes and achieving superior results.

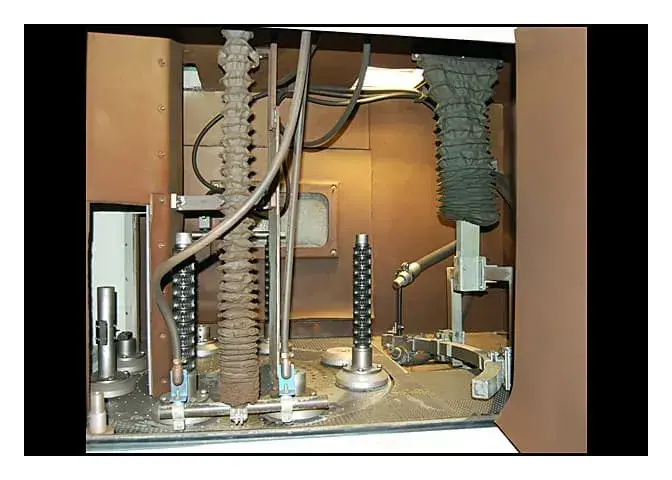

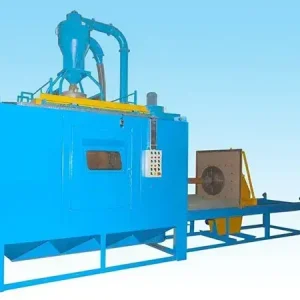

Trusted shot peening machine manufacturers in Ghaziabad offer a diverse range of equipment, catering to various application requirements and production scales. From compact, bench-top models suitable for small-scale operations to fully automated systems for high-volume manufacturing, these manufacturers deliver solutions tailored to the unique needs of each industry sector. Their expertise in precision engineering ensures that their shot peening machines deliver consistent results while minimizing material waste and production downtime.

Furthermore, renowned manufacturers prioritize innovation and quality assurance throughout the manufacturing process, utilizing state-of-the-art technology and materials to produce robust, reliable machines. By adhering to stringent quality standards and industry regulations, they guarantee the performance, durability, and safety of their equipment, providing customers with peace of mind and confidence in their investment.

In addition to offering high-quality equipment, top shot peening machine manufacturers in Ghaziabad provide comprehensive support services, including installation, training, maintenance, and technical assistance. Their experienced teams collaborate closely with clients to understand their specific requirements and operational challenges, offering tailored solutions and ongoing support to optimize machine performance and productivity.

The AeroWheel Surface Finishing Solution

AeroWheel Surface Finishing introduces a game-changer to Ghaziabad manufacturers with our advanced Shot Peening Machines. Discover the advantages:

- Enhanced Component Lifespan: Create compressive stress layers for improved fatigue resistance and reduced failures.

- Increased Surface Hardness: Improve strength and wear resistance of critical parts.

- Precision Control: Achieve the precise surface finish and peening intensity required for your application.

- Versatility: Suitable for a wide range of components and materials.

- Efficiency Boost: Reduced downtime and maintenance compared to alternative hardening techniques.

Features and Customization

AeroWheel Surface Finishing’s Shot Peening Machines are engineered for your specific needs:

- Diverse Machine Options: Choose from air-operated, wheel-driven, or specialized peening systems.

- Advanced Controls: Fine-tune peening intensity, shot flow, and coverage area.

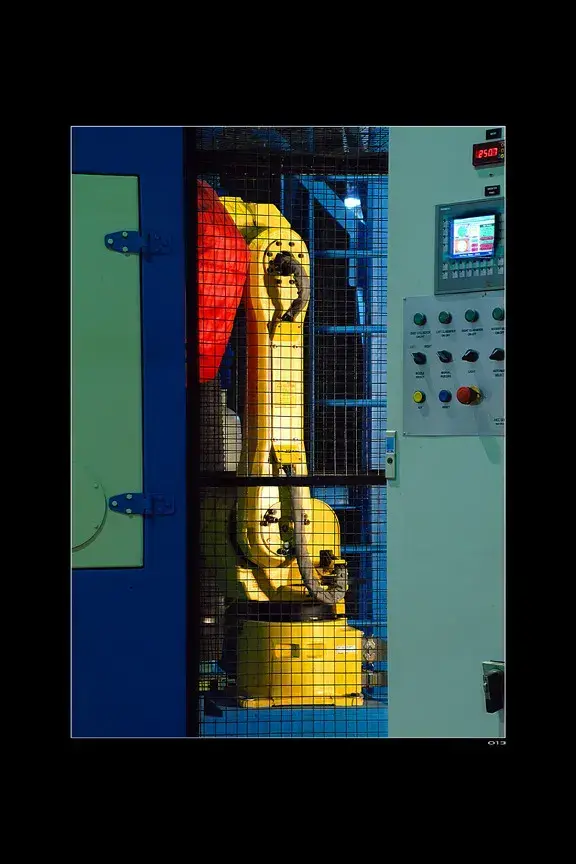

- Automated Features: Integrate with production lines for seamless workflow.

- Component Fixturing: Customized fixturing to ensure precise and repeatable peening results.

Why Choose AeroWheel Surface Finishing

For the highest quality Shot Peening Machines in Ghaziabad, manufacturers choose AeroWheel because:

- Expertise in Surface Enhancement: We understand the science behind shot peening and its benefits.

- Proven Results: A history of delivering increased part lifespan for clients across industries.

- Tailored Solutions: Machines custom-configured to match your parts and production volume.

- Ongoing Support: Installation, training, maintenance, and Almen strip calibration services.

Call to Action

Invest in lasting component reliability in Ghaziabad. Contact AeroWheel Surface Finishing to discuss your Shot Peening Machine requirements and learn how we can transform your operations.

In conclusion, for businesses in Ghaziabad seeking advanced shot peening solutions to enhance surface integrity and component performance, partnering with reputable manufacturers is crucial. By leveraging the expertise, innovation, and support services of leading manufacturers, businesses can access cutting-edge shot peening machines tailored to their industrial needs. Invest in reliability, efficiency, and performance with premier shot peening machine manufacturers in Ghaziabad, and elevate your surface treatment processes to new heights of excellence.

Reviews

There are no reviews yet.