Suction/Vacuum Blast Cabinet Manufacturers in Ghaziabad: Precision Blasting Solutions from AeroWheel

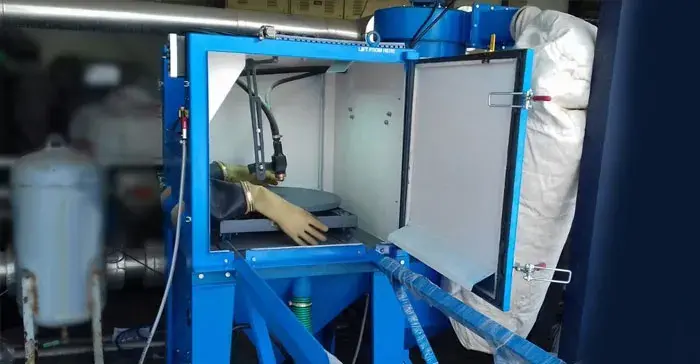

If you’re seeking premium suction/vacuum blast cabinets in Ghaziabad, look no further than AeroWheel Surface Finishing. We specialize in designing and manufacturing cutting-edge cabinets engineered for precision, safety, and efficiency in diverse blasting applications.

Why Choose AeroWheel for Ghaziabad Blasting Needs

- Local Expertise: We understand Ghaziabad’s industrial landscape and the unique blasting requirements of businesses in the region.

- Advanced Engineering: Our cabinets incorporate the latest technologies for optimal cleaning and finishing outcomes.

- Safety-Centric Design: We prioritize operator safety and environmental responsibility.

- Customization Expertise: We’ll tailor the cabinet to perfectly match your parts and processes.

Understanding Suction/Vacuum Blasting

These cabinets offer a controlled environment for cleaning, deburring, or imparting delicate finishes to workpieces. They excel when using lightweight abrasives and offer these advantages:

- Versatility: Handle a wide variety of workpiece shapes, sizes, and materials.

- Precision: Ideal for intricate components or tasks requiring fine control over the finish.

- Cleaner Operation: Built-in dust collection keeps the work environment safe.

- Cost-Effective: Reduced abrasive consumption and lower air requirements.

Ghaziabad Industries that Benefit

- Precision Manufacturing: Achieve the exact surface requirements for critical components.

- Metal Fabrication: Ensure clean, prepped surfaces for welding, painting, or other treatments.

- Automotive Restoration: Gently restore parts without damage.

- And Many More!

AeroWheel Suction Blast Cabinets: Key Features

- Robust Construction: Designed for longevity and minimal downtime.

- User-Friendly: Intuitive controls and simplified maintenance.

- Safety Compliant: Adherence to industry standards.

- Scalable: Options to match small-batch and high-volume production.

Let AeroWheel Transform Your Blasting

Contact us to discover the perfect suction/vacuum blast cabinet for your Ghaziabad operations. Experience the advantages of precision, safety, and customized solutions firsthand.

Reviews

There are no reviews yet.